Izisekelo Zokugxiviza Ngensimbi

I-Metal stamping inqubo yokukhiqiza esetshenziselwa ukuguqula amashidi ensimbi ayisicaba abe yizimo ezithile.Kuyinqubo eyinkimbinkimbi engahlanganisa inqwaba yamasu okwenza insimbi - ukuvala, ukubhoboza, ukugoba nokubhoboza, ukubala okumbalwa.

Kunezinkulungwane zezinkampani kulo lonke izwe ezihlinzeka ngezinsizakalo zokugxiviza izitembu zensimbi ukuletha izingxenye zezimboni zezimoto, i-aerospace, medical, nezinye izimakethe.Njengoba izimakethe zomhlaba zithuthuka, kunesidingo esikhulayo sezingxenye ezinkulu ezikhiqizwa ngokushesha zezingxenye eziyinkimbinkimbi.

Umhlahlandlela olandelayo ubonisa izinqubo ezihamba phambili namafomula avame ukusetshenziswa enqubweni yokuklama isitembu sensimbi futhi uhlanganisa namathiphu okufaka ukucatshangelwa kokunciphisa izindleko zibe izingxenye.

Izitembu Eziyisisekelo

Ukugxiviza - okubuye kubizwe ngokuthi ukucindezela - kuhilela ukubeka insimbi yeshidi eliyisicaba, kungaba ikhoyili noma ifomu elingenalutho, emshinini wokunyathelisa.Emshinini wokunyathelisa, ithuluzi kanye ne-die surface yakha insimbi ibe yisimo oyifunayo.Ukubhoboza, ukuvala, ukugoba, ukuhlanganisa, ukufaka i-embossing, kanye ne-flanging yiwo wonke amasu okugxiviza asetshenziselwa ukubumba insimbi.

Ngaphambi kokuthi kwakhiwe impahla, ochwepheshe bokugxiviza kufanele baklame ithuluzi ngobuchwepheshe bonjiniyela be-CAD/CAM.Le miklamo kufanele icace ngangokunokwenzeka ukuze kuqinisekiswe ukuthi i-punch ngayinye kanye nokugoba kugcina imvume efanele futhi, ngakho-ke, ingxenye yezinga eliphezulu.Imodeli ye-3D yethuluzi elilodwa ingaqukatha amakhulu ezingxenye, ngakho-ke inqubo yokuklama ivamise ukuba yinkimbinkimbi futhi idla isikhathi.

Uma umklamo wamathuluzi ususunguliwe, umkhiqizi angasebenzisa izinhlobonhlobo zemishini, ukugaya, i-EDM yocingo nezinye izinsizakalo zokukhiqiza ukuze aqedele ukukhiqizwa kwayo.

Izinhlobo Metal Stamping

Kunezinhlobo ezintathu ezinkulu zamasu okugxiviza ngensimbi: i-progressive, fourslide kanye ne-deep draw.

I-Progressive Die Stamping

I-Progressive die stamping ihlanganisa iziteshi eziningi, ngasinye sinomsebenzi ohlukile.

Okokuqala, i-strip metal ifakwa ngomshini wokucindezela oqhubekayo.I-strip iyaxebuka kancane isuka kukhoyili futhi iye emshinini wokucofa, lapho isiteshi ngasinye ethuluzini bese senza ukusika okuhlukile, ukubhoboza, noma ukugoba.Izenzo zesiteshi ngasinye ezilandelanayo zengeza emsebenzini weziteshi zangaphambilini, okuholela engxenyeni eqediwe.

Umkhiqizi kungase kudingeke ashintshe ngokuphindaphindiwe ithuluzi emshinini owodwa wokucindezela noma athathe izinkinobho eziningi, ngamunye enze isenzo esisodwa esidingekayo engxenyeni eqediwe.Ngisho kusetshenziswa imishini yokunyathelisa eminingi, izinsiza zemishini yesibili ngokuvamile zazidingeka ukuze kuqedwe ingxenye ethile.Ngaleso sizathu, i-progressive die stamping yisisombululo esifaneleizingxenye zensimbi ezinejometri eyinkimbinkimbiukuhlangana:

- Ukushintsha ngokushesha

- Izindleko zabasebenzi eziphansi

- Ubude bokugijima obufushane

- Ukuphindaphinda okuphezulu

I-Fourslide Stamping

I-Fourslide, noma i-multi-slide, ifaka ukuqondanisa okuvundlile namaslayidi amane ahlukene;ngamanye amazwi, amathuluzi amane asetshenziswa kanyekanye ukuze alolonge umsebenzi.Le nqubo ivumela ukusikeka okuyinkimbinkimbi kanye nokugoba okuyinkimbinkimbi ukuthuthukisa ngisho nezingxenye eziyinkimbinkimbi kakhulu.

Ukugxiviza isitembu sensimbi nge-fourslide kunganikeza izinzuzo ezimbalwa ngaphezu kokugxiviza okuvamile okukwenza kube ukukhetha okuhle ezinhlelweni eziningi.Ezinye zalezi zinzuzo zihlanganisa:

1.Ukuhlukahluka kwezingxenye eziyinkimbinkimbi

2.Ukuguquguquka okwengeziwe kwezinguquko zedizayini

Njengoba igama layo lisho, i-fourslide inamaslayidi amane - okusho ukuthi amathuluzi afinyelela kwamane ahlukene, elilodwa kwisilayidi ngasinye, angasetshenziswa ukuzuza ukugoba okuningi ngesikhathi esisodwa.Njengoba impahla ingena ku-fourslide, igotshwa ngokulandelana ngokushesha yi-shaft ngayinye efakwe ithuluzi.

Ukugxiviza kwe-Draw Deep

Ukudweba okujulile kuhilela ukudonsa insimbi yeshidi ingenalutho edayilini ngokusebenzisa isibhakela, ukulenza libe yisimo.Indlela ibizwa ngokuthi "umdwebo ojulile" lapho ukujula kwengxenye edwetshiwe kudlula ububanzi bayo.Lolu hlobo lokubunjwa lufanelekile ekudaleni izingxenye ezidinga uchungechunge oluningana lwamadayamitha futhi luyindlela engabizi kakhulu yezinqubo zokuphenduka, ngokuvamile ezidinga ukusebenzisa izinto zokusetshenziswa ezengeziwe.Izinhlelo zokusebenza ezijwayelekile kanye nemikhiqizo eyenziwe ngomdwebo ojulile ihlanganisa:

1.Izingxenye zezimoto

2.Izingxenye zendiza

3.Ukudluliselwa kwe-elekthronikhi

4.Izitsha nezinto zokupheka

Ukugxiviza kwe-Draw Deep

Ukudweba okujulile kuhilela ukudonsa insimbi yeshidi ingenalutho edayilini ngokusebenzisa isibhakela, ukulenza libe yisimo.Indlela ibizwa ngokuthi "umdwebo ojulile" lapho ukujula kwengxenye edwetshiwe kudlula ububanzi bayo.Lolu hlobo lokubunjwa lufanelekile ekudaleni izingxenye ezidinga uchungechunge oluningana lwamadayamitha futhi luyindlela engabizi kakhulu yezinqubo zokuphenduka, ngokuvamile ezidinga ukusebenzisa izinto zokusetshenziswa ezengeziwe.Izinhlelo zokusebenza ezijwayelekile kanye nemikhiqizo eyenziwe ngomdwebo ojulile ihlanganisa:

1.Izingxenye zezimoto

2.Izingxenye zendiza

3.Ukudluliselwa kwe-elekthronikhi

4.Izitsha nezinto zokupheka

I-Short Run Stamping

Ukugxiviza izitembu zensimbi okufushane kudinga izindleko ezincane zamathuluzi angaphambili futhi kungaba yisixazululo esifanelekile sama-prototypes noma amaphrojekthi amancane.Ngemuva kokuthi kudalwe okungenalutho, abakhiqizi basebenzisa inhlanganisela yezingxenye zamathuluzi zangokwezifiso kanye nokufaka ukufa ukuze bagobe, babhoboze noma babhoboze ingxenye.Ukusebenza kokwenza ngokwezifiso kanye nosayizi omncane wokugijima kungabangela inkokhiso ephezulu ngocezu ngalunye, kodwa ukungabi bikho kwezindleko zamathuluzi kungenza ukusebenza okufushane kubize kakhulu kumaphrojekthi amaningi, ikakhulukazi lawo adinga ukushintshwa ngokushesha.

Amathuluzi Okukhiqiza Wokugxiviza

Kunezinyathelo ezimbalwa zokukhiqiza isitembu sensimbi.Isinyathelo sokuqala ukuklama nokukhiqiza ithuluzi langempela elisetshenziselwa ukudala umkhiqizo.

Ake sibheke ukuthi leli thuluzi lokuqala lenziwa kanjani:Isakhiwo Nokwakheka Kwesitoko:Umklami osetshenziswayo usetshenziselwa ukuklama umugqa futhi anqume ubukhulu, ukubekezelela, isiqondiso sokuphakelayo, ukuncishiswa kwe-scrap nokuningi.

Ithuluzi Lensimbi ne-Die Set Machining:I-CNC iqinisekisa izinga eliphezulu lokunemba nokuphindaphinda ngisho nokufa okuyinkimbinkimbi kakhulu.Izisetshenziswa ezifana nezigayo ze-CNC ze-axis ezingu-5 nocingo zinganqamula izinsimbi zamathuluzi aqinile ezinokubekezelelana okuqine kakhulu.

Ukucutshungulwa Kwesibili:Ukwelapha ukushisa kusetshenziswa ezingxenyeni zensimbi ukuze kuthuthukiswe amandla azo futhi kuzenze ziqine ngokwengeziwe ekusetshenzisweni kwazo.Ukugaya kusetshenziselwa ukuqedela izingxenye ezidinga ikhwalithi ephezulu yendawo kanye nokunemba kobukhulu.

I-EDM yocingo:Intambo yokukhipha ugesi ibumba izinto zensimbi ngomucu oshajwa ngogesi wocingo lwethusi.I-EDM yocingo ingasika izimo eziyinkimbinkimbi kakhulu, kufaka phakathi ama-engeli amancane namakhonco.

Metal Stamping Design Izinqubo

Ukugxiviza ngensimbi kuyinqubo eyinkimbinkimbi engahlanganisa izinqubo eziningana zokwakha insimbi—ukuvala, ukubhoboza, ukugoba, nokubhoboza nokunye.Ukungasho lutho:Le nqubo imayelana nokusika uhlaka noma umumo womkhiqizo.Lesi sigaba simayelana nokunciphisa nokugwema ama-burrs, angakhuphula izindleko zengxenye yakho futhi andise isikhathi sokuhola.Isinyathelo yilapho unquma khona ububanzi bembobo, i-geometry/taper, isikhala phakathi konqenqema nomgodi bese ufaka ukubhoboza kokuqala.

Ukugoba:Uma uklama ukugoba engxenyeni yakho yensimbi enesitembu, kubalulekile ukuvumela impahla eyanele - qiniseka ukuthi uklama ingxenye yakho kanye nokungenalutho kwayo ukuze kube nezinto ezanele zokwenza ukugoba.Ezinye izici ezibalulekile okufanele uzikhumbule:

1.Uma ukugoba kwenziwa eduze kakhulu nomgodi, kungakhubazeka.

2.Notches namathebhu, kanye nezikhala, kufanele kuklanywe ngobubanzi okungenani obungu-1.5x ubukhulu bento.Uma zenziwe zibe zincane, zingaba nzima ukuzidala ngenxa yamandla asetshenziswa ezibhakeleni, ezibangela ukuthi ziphuke.

3.Wonke amakhona ekwakhiweni kwakho okungenalutho kufanele abe nerediyasi okungenani enguhhafu wogqinsi lwezinto.

4.Ukuze unciphise izimo kanye nobukhulu bama-burrs, gwema amakhona acijile kanye nokusika okuyinkimbinkimbi lapho kungenzeka.Uma izici ezinjalo zingenakugwenywa, qiniseka ukuthi uphawula isiqondiso se-burr ekwakhiweni kwakho ukuze zicatshangelwe ngesikhathi sokugxiviza.

Ukwenza imaliLesi senzo yilapho amaphethelo engxenye yensimbi enesitembu eshaywa ukuze enze isicaba noma aphule i-burr;lokhu kungakha unqenqema olubushelelezi kakhulu endaweni ehlanganisiwe yengxenye yejometri;lokhu kungase futhi kwengeze amandla engeziwe ezindaweni zasendaweni zengxenye futhi lokhu kungasetshenziswa ukugwema inqubo yesibili efana nokususa nokugaya.Ezinye izici ezibalulekile okufanele uzikhumbule:

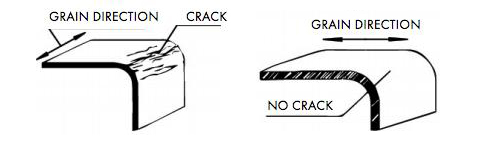

Ipulasitiki kanye nesiqondiso sokusanhlamvu- I-Plasticity iyisilinganiso sokuguga unomphela into eyenziwayo lapho iphoqelelwa.Izinsimbi ezine-plasticity eyengeziwe kulula ukwakha.Isiqondiso sokusanhlamvu sibalulekile ezintweni ezinamandla kakhulu, njengezinsimbi ezipholile kanye nensimbi engagqwali.Uma ukugoba kuhambisana nokusanhlamvu kwamandla aphezulu, kungase kuthambekele ekuqhekekeni.

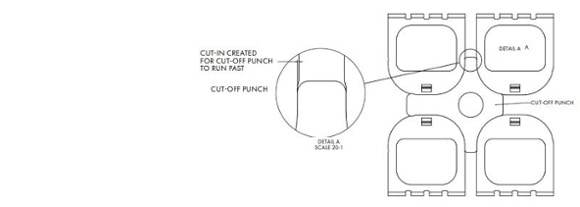

I-Gobela Ukuhlanekezela/I-Bulge:Ukuqunjelwa okubangelwa ukuhlanekezela kwegoba kungaba kukhulu njengo-½ ubukhulu bezinto ezibonakalayo.Njengoba ukushuba kwezinto kukhula futhi irediyasi yokugoba iyancipha ukuhlanekezela/iqhubu kuba nzima kakhulu.I-Web Carry and “Mismatch” Cut:Kulapho kudingeka khona ukusika noma ukushayisana kancane engxenyeni futhi ngokuvamile cishe kujule ngo-.005”.Lesi sici akudingekile uma kusetshenziswa amathuluzi okuhlanganisa noma ohlobo lokudlulisa kodwa siyadingeka uma kusetshenziswa ithuluzi lokufa eliqhubekayo.

Ingxenye Egxiviziwe Ngokwezifiso Yezisetshenziswa Ezibalulekile Zokuqapha Embonini Yezokwelapha

Iklayenti embonini yezokwelapha laya ku-MK ukuze kugxivizwe isitembu sensimbi ngokwezifiso ingxenye ezosetshenziswa njengesihlangu sentwasahlobo nese-electronics emishinini yokuqapha ebalulekile emkhakheni wezokwelapha.

1.Babedinga ibhokisi lensimbi engagqwali elinezici zethebhu yasentwasahlobo futhi bebenenkinga yokuthola umphakeli ozohlinzeka ngedizayini yekhwalithi ephezulu ngentengo ethengekayo ngaphakathi komugqa wesikhathi ozwakalayo.

2. Ukuze sihlangabezane nesicelo esiyingqayizivele seklayenti sokunamathisela ingxenye eyodwa kuphela yengxenye - esikhundleni sengxenye yonke - sibambisene nenkampani ehamba phambili embonini yokuhlanganisa ama-tin-plating ekwazile ukuthuthukisa inqubo ethuthukisiwe yonqenqema olulodwa, ekhethiwe.

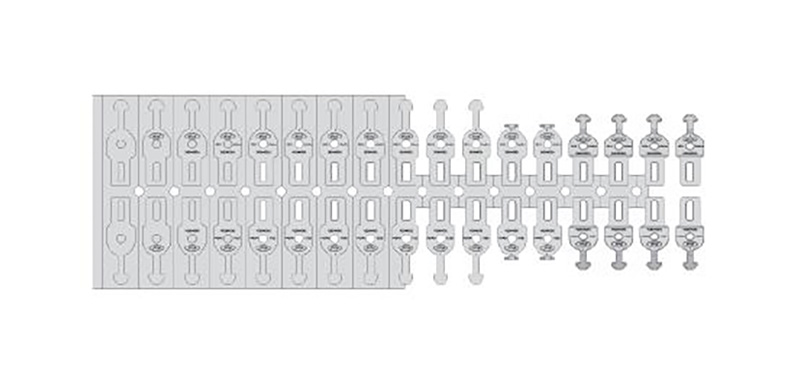

I-MK ikwazile ukuhlangabezana nezidingo zedizayini eziyinkimbinkimbi isebenzisa indlela yokunqwabelanisa impahla eyasivumela ukuba sinqamule izingxenye eziningi ezingenalutho ngesikhathi esisodwa, sinciphise izindleko futhi sinciphise izikhathi zokuhola.

Isixhumi sikagesi esigxiviziwe sohlelo lwezintambo kanye nekhebula

1.Umklamo wawuyinkimbinkimbi kakhulu;la makhava ayehloselwe ukuthi asetshenziswe njengezintambo zikagesi ngaphakathi nangaphansi kwemigwaqo kagesi ephansi nangaphansi;ngakho-ke, lolu hlelo lokusebenza lwethule imikhawulo yosayizi eqinile.

2.Inqubo yokukhiqiza yayiyinkimbinkimbi futhi ibiza, njengoba eminye yemisebenzi yekhasimende idinga ikhava egcwaliswe ngokugcwele kanti eminye yayingakwenzi lokho - okusho ukuthi i-AFC ibikade yenza izingxenye zibe izingcezu ezimbili futhi izishisela ndawonye lapho kudingeka.

3.Sisebenza ngesembozo sesixhumi esiyisampula kanye nethuluzi elilodwa elinikezwe iklayenti, ithimba lethu kwa-MK likwazile ukuhlehlisa unjiniyela ingxenye kanye nethuluzi layo.Kusukela lapha, siklame ithuluzi elisha, ebesingalisebenzisa emshinini wethu wokunyathelisa we-Bliss progressive stamping we-150-ton.

4.Lokhu kwasivumela ukuthi senze ingxenye engxenyeni eyodwa enezingxenye ezishintshayo, kunokuba sikhiqize izingcezu ezimbili ezihlukene njengoba iklayenti belikade lenza.

Lokhu kuvumele ukonga kwezindleko ezibalulekile - isaphulelo esingu-80% ezindlekweni ze-oda eliyingxenye engu-500,000 - kanye nesikhathi sokuhola samasonto amane kunezingu-10.

Ukugxiviza Ngokwezifiso Kwama-Airbag Ezimoto

Iklayenti lezimoto lalidinga i-grommet yensimbi enamandla amakhulu, ekwazi ukumelana nokucindezela ukuze isetshenziswe kuma-airbag.

1. Ngomdwebo ongu-34 mm x 18 mm x 8 mm, i-grommet idinga ukugcina ukubekezelela okungu-0.1 mm, kanye nenqubo yokukhiqiza edingekayo ukuze kufakwe izinto ezihlukile ezinwebekayo ezitholakala ohlelweni lokugcina.

2. Ngenxa yejiyomethri yayo ehlukile, i-grommet ayikwazanga ukukhiqizwa kusetshenziswa ithuluzi lokucindezela lokudlulisa futhi ukudweba kwayo okujulile kwethule inselele eyingqayizivele.

Ithimba le-MK lakha ithuluzi eliqhubekayo leziteshi ezingama-24 ukuze liqinisekise ukuthuthukiswa okufanele komdwebo futhi lasebenzisa insimbi ye-DDQ ene-zinc plating ukuze kuqinisekiswe amandla afanele kanye nokumelana nokugqwala.Ukugxiviza kwensimbi kungasetshenziswa ukwakha izingxenye eziyinkimbinkimbi zohlu olukhulu lwezimboni.Ufuna ukwazi okwengeziwe mayelana nezinhlelo zokusebenza zokugxiviza zensimbi ngokwezifiso esisebenze kuzo?Vakashela ikhasi lethu le-Case Studies, noma thintana nethimba le-MK ngokuqondile ukuze uxoxe ngezidingo zakho ezihlukile nochwepheshe.