I-Photochemical Metal Etching

Ukusebenzisa i-Computer Aid Design (CAD)

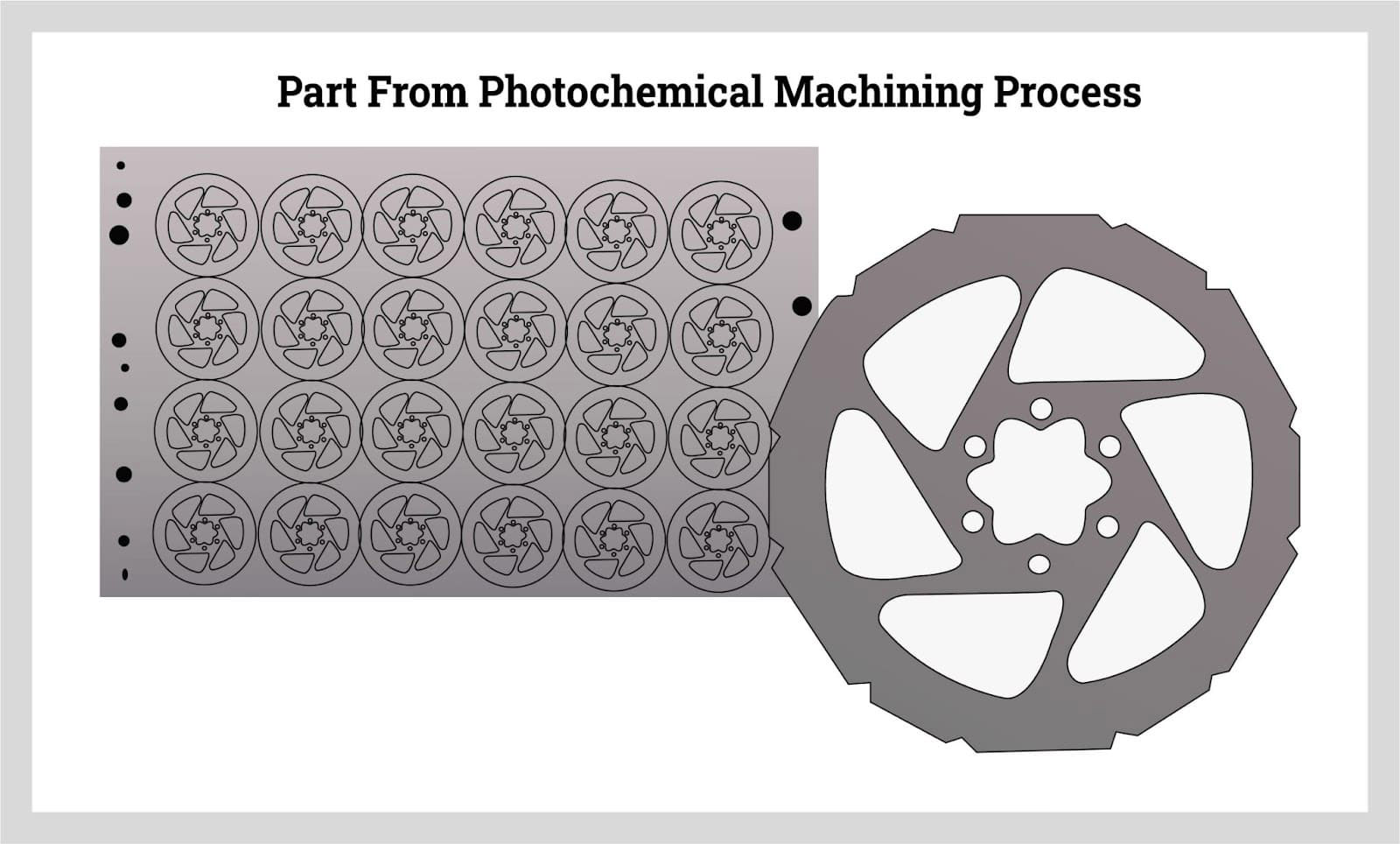

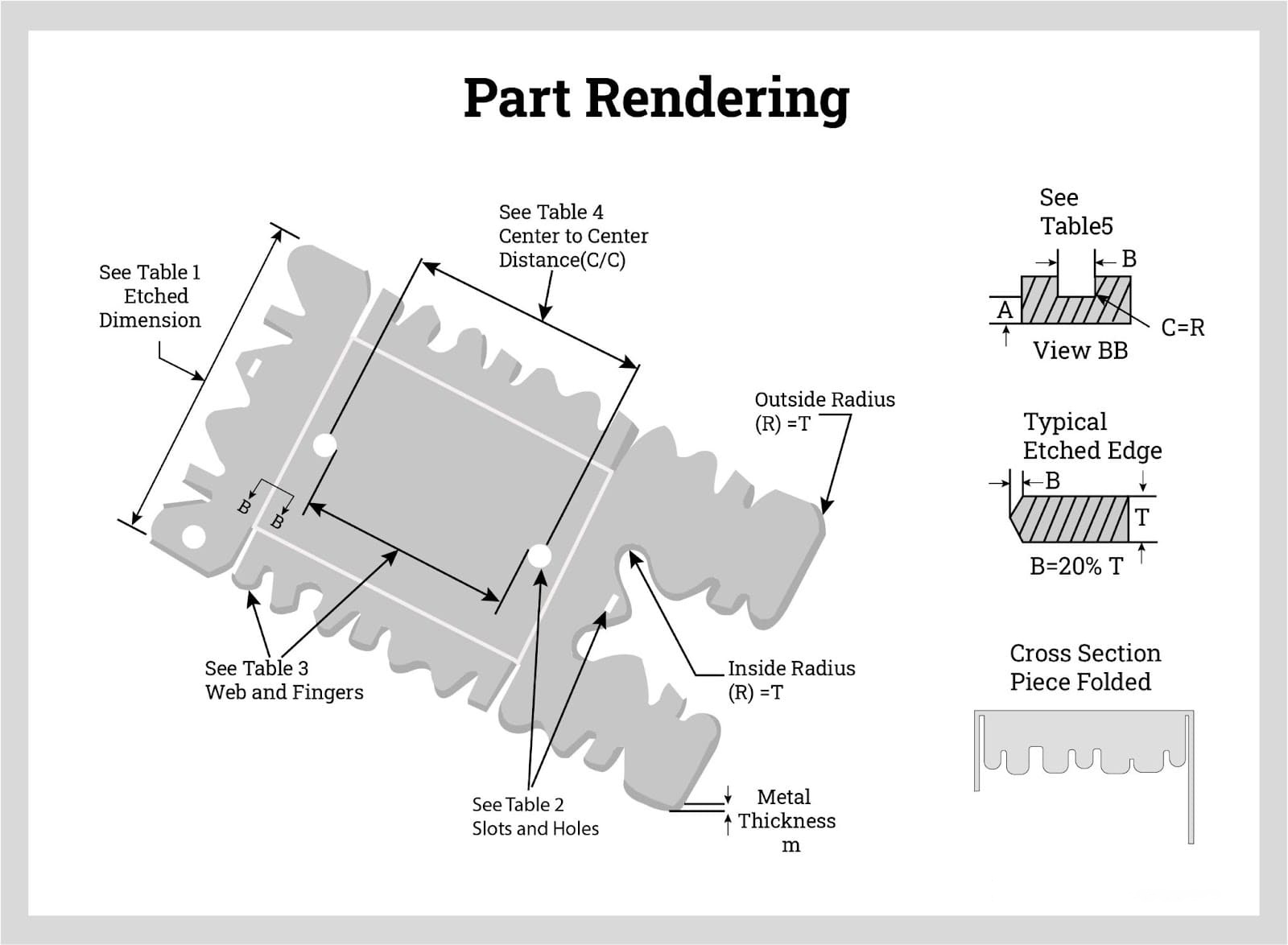

Inqubo yokufaka i-photochemical metal etching iqala ngokwakhiwa kwedizayini kusetshenziswa i-CAD noma i-Adobe Illustrator.Nakuba ukuklama kuyisinyathelo sokuqala senqubo, akusona isiphetho sezibalo zekhompyutha.Uma ukukhishwa sekuqediwe, ukujiya kwensimbi kuyanqunywa kanye nenani lezingcezu ezizongena eshidini, into edingekayo yokwehlisa izindleko zokukhiqiza.Isici sesibili sobukhulu beshidi ukunqunywa kokubekezelelana kwengxenye, okuncike kubukhulu bengxenye.

Inqubo yokufaka i-photochemical metal etching iqala ngokwakha idizayini usebenzisa i-CAD noma i-Adobe Illustrator.Nokho, lesi akusona ukuphela kwesibalo sekhompyutha esihilelekile.Ngemva kokuqeda umklamo, ubukhulu bensimbi bunqunywa, kanye nenani lezicucu ezingangena eshidini ukuze kuncishiswe izindleko zokukhiqiza.Ukwengeza, ukubekezelelana kwengxenye kuncike kubukhulu bengxenye, ebuye ibe nobukhulu beshidi.

Metal Ukulungiselela

Njengokufaka i-asidi, insimbi kufanele ihlanzwe kahle ngaphambi kokuba icutshungulwe.Ucezu ngalunye lwensimbi luyakhuhlwa, luhlanzwe futhi luhlanzwe kusetshenziswa umfutho wamanzi kanye ne-solvent ethambile.Le nqubo iqeda amafutha, ukungcola, nezinhlayiya ezincane.Lokhu kuyadingeka ukuze unikeze indawo ehlanzekile ebushelelezi ukuze kusetshenziswe ifilimu ye-photoresist ukunamathela ngokuphephile.

Laminating Metal Amashidi Ngamafilimu Photoresistant

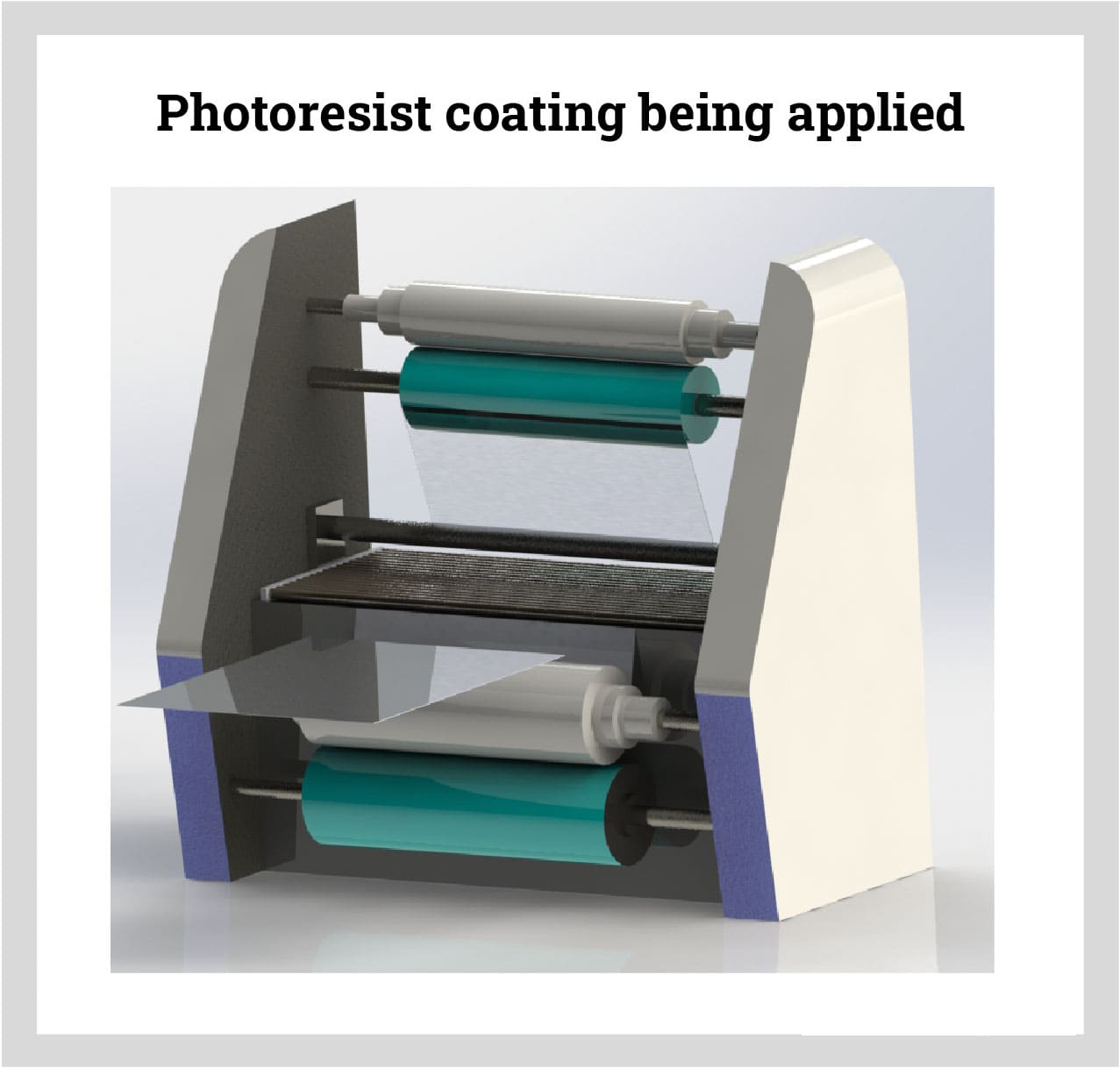

I-Lamination ukusetshenziswa kwefilimu ye-photoresist.Amashidi ensimbi ahanjiswa phakathi kwama-roller agqoke futhi asebenzise ngokulinganayo i-lamination.Ukuze ugweme noma yikuphi ukuchayeka okungadingekile kwamashidi, inqubo iqedelwa ekamelweni elikhanyiswe ngezibani eziphuzi ukuze kuvinjelwe ukuchayeka kokukhanya kwe-UV.Ukuqondanisa kahle amashidi kunikezwa izimbobo ezishaywa emaphethelweni amashidi.Ama-Bubbles ekugqokeni kwe-laminated avinjelwa ngokuvala amashidi nge-vacuum, ebeka izingqimba ze-laminate.

Ukuze ulungise insimbi ye-photochemical metal etching, kufanele ihlanzwe kahle ukuze kukhishwe amafutha, ukungcola, nezinhlayiya.Ingxenye ngayinye yensimbi iyakhuhlwa, ihlanzwe, futhi igezwe nge-solvent encane kanye nokucindezela kwamanzi ukuze kuqinisekiswe indawo ebushelelezi, ehlanzekile yokusetshenziswa kwefilimu ye-photoresist.

Isinyathelo esilandelayo yi-lamination, okubandakanya ukusebenzisa ifilimu ye-photoresist kumashidi ensimbi.Amashidi ahanjiswa phakathi kwama-rollers ukuze agqoke ngokulinganayo futhi asebenzise ifilimu.Inqubo yenziwa egumbini elinokukhanya okuphuzi ukuvikela ukuchayeka kokukhanya kwe-UV.Izimbobo ezibhotshozwe emaphethelweni amashidi zinikeza ukuqondana okufanele, kuyilapho ukuvala kwe-vacuum kucaba izingqimba ze-laminate futhi kuvimbela amabhamuza ukuthi akheke.

Ukucutshungulwa kwe-Photoresist

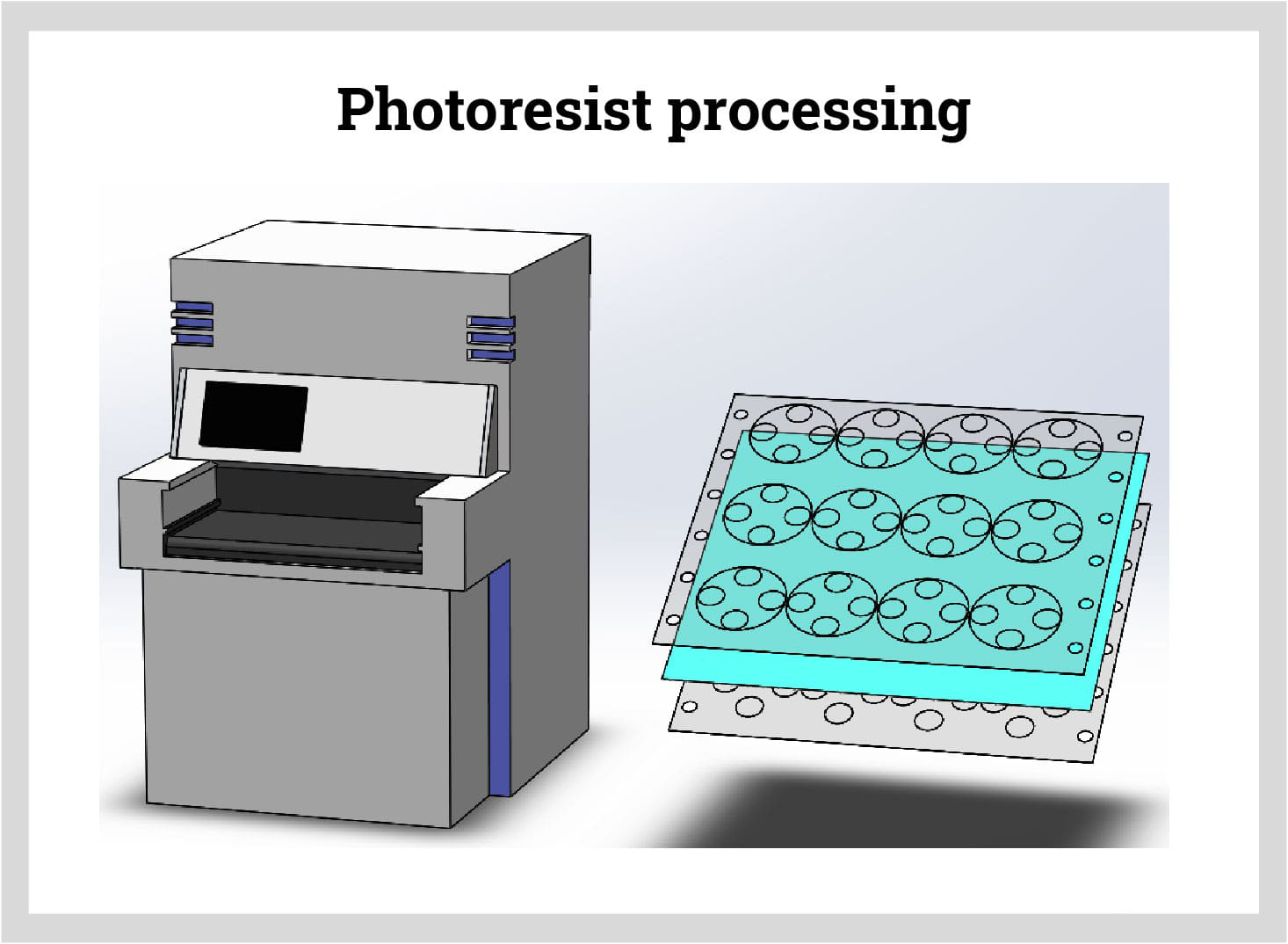

Ngesikhathi sokucutshungulwa kwe-photoresist, izithombe eziphuma ekunikezelweni kwe-CAD noma kwe-Adobe Illustrator zibekwa kungqimba lwe-photoresist eshidini lensimbi.Ukunikezwa kwe-CAD noma kwe-Adobe Illustrator kuphrintiwe ezinhlangothini zombili zeshidi lensimbi ngokuyihlanganisa ngapha nangapha kwensimbi.Uma amashidi ensimbi esenezithombe ezisetshenzisiwe, avezwa ukukhanya kwe-UV okubeka izithombe unomphela.Lapho ukukhanya kwe-UV kukhanya ezindaweni ezicacile ze-laminate, i-photoresist iyaqina futhi iqine.Izindawo ezimnyama ze-laminate zihlala zithambile futhi zingathonywa ukukhanya kwe-UV.

Esigabeni sokucutshungulwa kwe-photoresist se-photochemical metal etching, izithombe ezisuka kumklamo we-CAD noma we-Adobe Illustrator zidluliselwa kungqimba lwe-photoresist eshidini lensimbi.Lokhu kwenziwa ngokuhlanganisa umklamo phezu nangaphansi kweshidi lensimbi.Uma izithombe sezifakwe eshidini lensimbi, zivezwa ukukhanya kwe-UV, okwenza izithombe zibe unomphela.

Ngesikhathi sokuchayeka kwe-UV, izindawo ezicacile ze-laminate zivumela ukukhanya kwe-UV ukuthi kudlule, okwenza i-photoresist ibe lukhuni futhi iqine.Ngokuphambene, izindawo ezimnyama ze-laminate zihlala zithambile futhi zingathinteki ukukhanya kwe-UV.Le nqubo idala iphethini ezoqondisa inqubo yokufaka, lapho izindawo eziqinile zizohlala khona futhi izindawo ezithambile zizoqoshwa.

Ukuthuthukisa AmaSpredishithi

Kusukela ekucutshungulweni kwe-photoresist, amashidi aya emshinini okhulayo osebenzisa isixazululo se-alkali, ikakhulukazi izixazululo ze-sodium noma ze-potassium carbonate, ezigeza ifilimu ethambile ye-photoresist eshiya izingxenye ukuthi zifakwe obala.Inqubo isusa ukumelana okuthambile futhi ishiya ukumelana okuqinile, okuyingxenye okufanele iqoshwe.Esithombeni esingezansi, izindawo eziqinile ziluhlaza okwesibhakabhaka, futhi izindawo ezithambile zimpunga.Izindawo ezingavikelwe yi-laminate eqinile ziyinsimbi eveziwe ezokhishwa ngesikhathi sokuqoshwa.

Ngemuva kwesiteji sokucubungula i-photoresist, amashidi ensimbi abe esedluliselwa emshinini okhulayo lapho kusetshenziswa isisombululo se-alkali, ngokuvamile i-sodium noma i-potassium carbonate.Lesi sixazululo sigeza ifilimu ethambile ye-photoresist, ishiye izingxenye ezidinga ukuqoshwa zivezwe.

Ngenxa yalokho, ukumelana okuthambile kuyasuswa, kuyilapho ukumelana okunzima, okuhambisana nezindawo ezidinga ukuqoshwa, kushiywe ngemuva.Ephethinini eliphumela, izindawo eziqinile zikhonjiswa ngokuluhlaza okwesibhakabhaka, futhi izindawo ezithambile zimpunga.Izindawo ezingavikelwe ukumelana okuqinile zimelela insimbi eveziwe ezosuswa ngesikhathi sokuqopha.

Etching

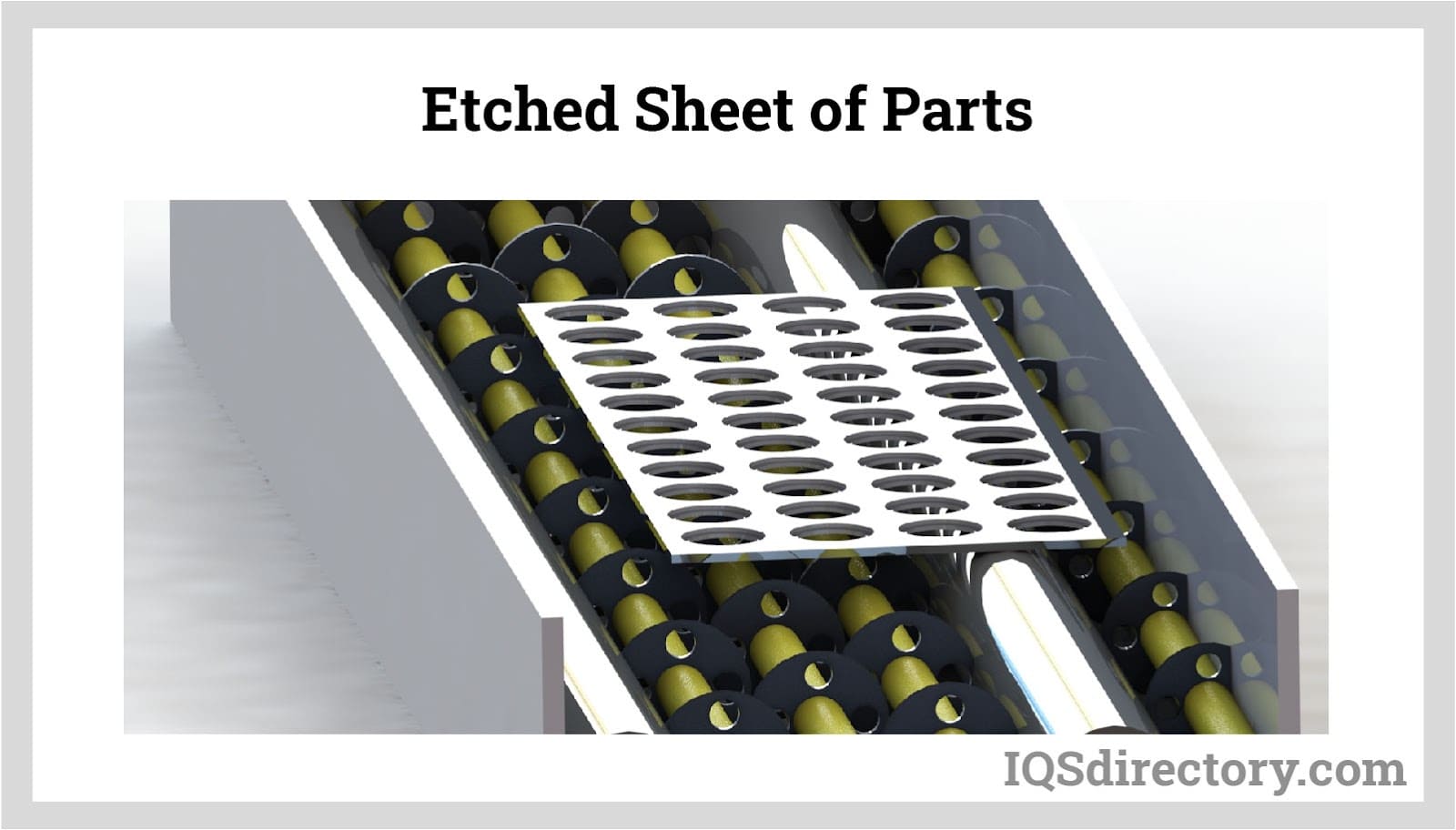

Ngokufana nenqubo yokunamathisela i-asidi, amashidi athuthukisiwe abekwa kumshini wokuhambisa amaphepha ohambisa amaphepha ngomshini othela i-etchant emakhasini.Lapho i-etchant ihlangana nensimbi eveziwe, incibilikisa insimbi ishiya okokusebenza okuvikelekile.

Ezinqubweni eziningi ze-photochemical, i-etchant i-ferric chloride, efuthwa kusukela phansi nangaphezulu kwesithumeli.I-Ferric chloride ikhethwa njenge-etchant ngoba iphephile ukuyisebenzisa futhi igaywa kabusha.I-Cutric chloride isetshenziselwa ukufaka ithusi nama-alloys ayo.

Inqubo yokunamathisela kufanele ibekwe isikhathi ngokucophelela futhi ilawulwe ngokuhambisana nensimbi eqoshwayo njengoba ezinye izinsimbi zithatha isikhathi eside ukushumeka kunezinye.Ukuze kuphumelele ukushumeka kwe-photochemical, ukuqapha nokulawula ngokucophelela kubalulekile.

Esigabeni sokuqopha sokushumeka kwensimbi ye-photochemical, amashidi ensimbi athuthukisiwe abekwa ku-conveyor ewahambisa ngomshini lapho i-etchant ithululelwa emakhasini.I-etchant incibilikisa insimbi eveziwe, ishiya ngemuva izindawo ezivikelekile zeshidi.

I-Ferric chloride ivame ukusetshenziswa njenge-etchant ezinqubweni eziningi zamakhemikhali ezithombe ngoba iphephile ukuyisebenzisa futhi ingagaywa kabusha.Kwethusi kanye nama-alloys ayo, i-cupric chloride isetshenziswa esikhundleni salokho.

Inqubo yokunamathisela kufanele imiswe ngokucophelela futhi ilawulwe ngokuya ngohlobo lwensimbi eqoshwayo, njengoba ezinye izinsimbi zidinga izikhathi zokuqopha ezinde kunezinye.Ukuqinisekisa impumelelo yenqubo yokufaka ama-photochemical, ukuqapha nokulawula ngokucophelela kubalulekile.

Ukuhlubula Ifilimu Yokuphikisa Esele

Phakathi nenqubo yokuhlubula, i-stripper yokumelana isetshenziswa ezicucu ukuze kususwe noma iyiphi ifilimu esele yokumelana.Lapho ukuhlubula sekuqediwe, ingxenye eqediwe iyasala, engabonakala esithombeni esingezansi.

Ngemuva kwenqubo yokufaka, ifilimu yokumelana esele ephepheni lensimbi iyasuswa ngokufaka i-resist stripper.Le nqubo isusa noma iyiphi ifilimu yokumelana esele ebusweni beshidi lensimbi.

Uma inqubo yokuhlubula isiqediwe, ingxenye yensimbi eqediwe ishiywe, engabonakala esithombeni esiphumela.